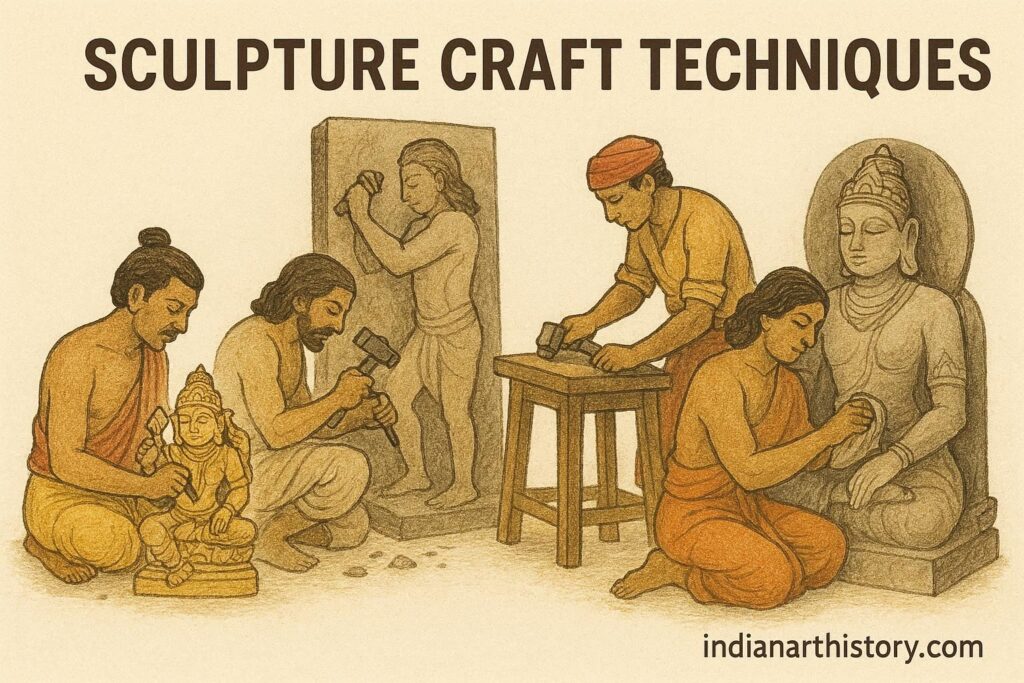

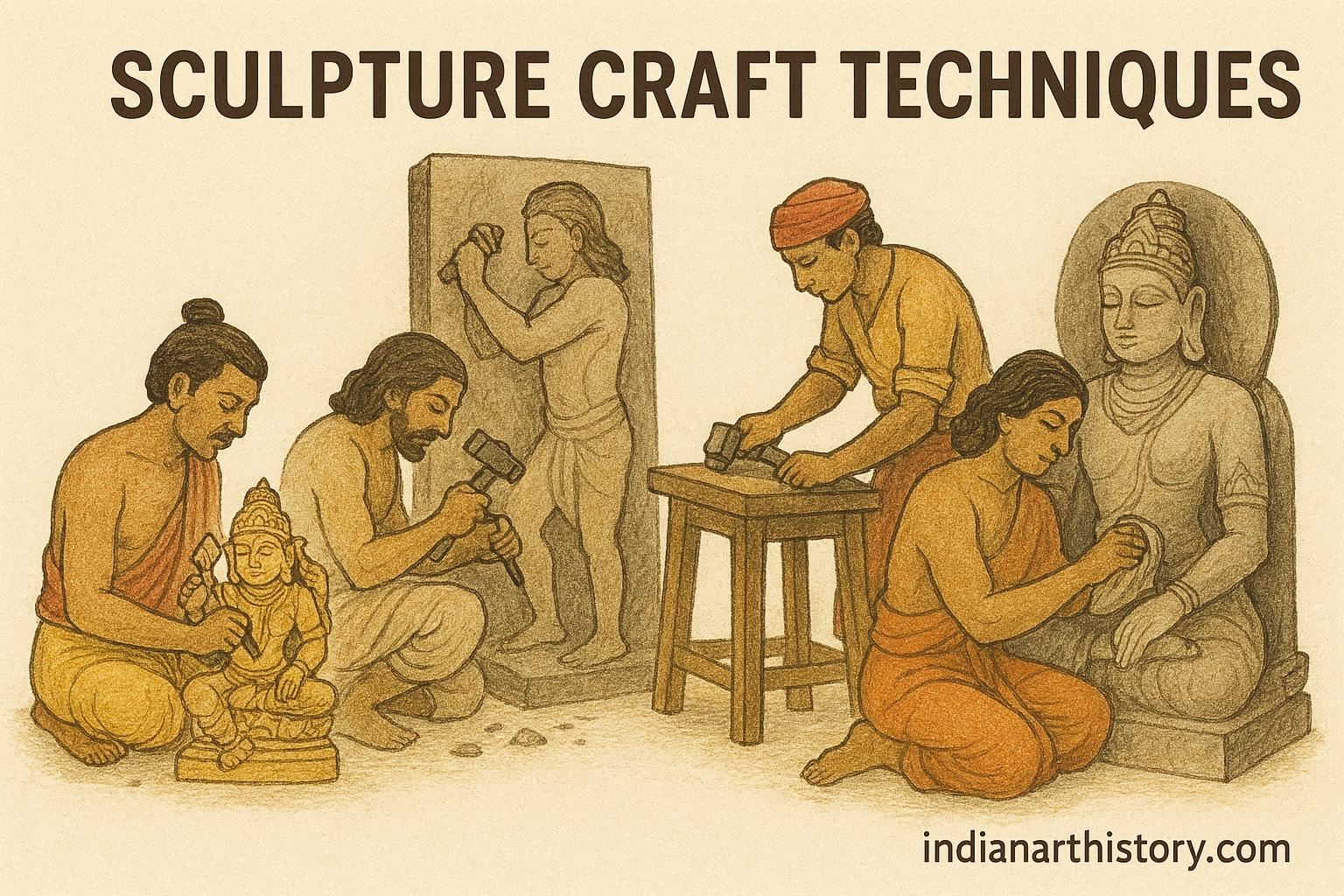

Sculpture and craft encompass three-dimensional art forms that transform materials into expressive objects. From ancient clay modeling to contemporary installations, these techniques allow artists to manipulate space, form, and texture in ways unique to physical making.

Table of Contents

Sculptural Techniques

Modeling (Additive Process)

Clay Modeling Clay is the most accessible sculptural material, allowing direct manipulation with hands and tools. Water-based clay remains workable until fired, enabling continual refinement. Build forms using coil methods (rolling clay into rope-like strands and stacking), slab construction (rolling flat sheets and joining), or pinch techniques (shaping from solid masses). Keep clay moist with damp cloths and spray bottles during work sessions.

Understanding clay’s behavior is essential. Earthenware fires at lower temperatures and remains porous. Stoneware fires hotter, becoming vitrified and durable. Porcelain, the finest clay, achieves translucency and pure white color at high temperatures. Polymer clays cure in home ovens, offering convenience without kiln requirements.

Hollow large forms to prevent cracking during drying and firing. Wall thickness should remain consistent (typically 1-2 cm). Score and slip (roughen surfaces and apply clay-water paste) when joining pieces. Support overhanging elements with temporary armatures or props. Allow sculptures to dry slowly, covered loosely to prevent cracking from uneven drying.

Wax Modeling Sculptors use wax for direct modeling and lost-wax casting. Modeling wax, available in various hardness levels, can be carved, melted, and reshaped. Warm wax with hands, heat tools, or alcohol lamps for malleability. Build up forms gradually, layering sheets or ribbons. Wax accepts fine detail and can be smoothed to glass-like finishes with heat or solvents.

Plaster Mix plaster powder with water for quick-setting modeling material. Work rapidly as plaster heats and hardens within 20-40 minutes. Build up forms over armatures, carve while semi-hard, or pour into molds. Plaster accepts paint, carving, and surface textures. However, it’s fragile and unsuitable for outdoor placement without protection.

Carving (Subtractive Process)

Stone Carving Stone carving removes material to reveal forms within. Soft stones like soapstone, alabaster, and limestone suit beginners. Harder stones—marble and granite—require experience and specialized tools. Point chisels remove large amounts, flat chisels refine planes, and toothed chisels create textures. Rasps and rifflers smooth surfaces before finishing with abrasives.

Work cautiously; mistakes cannot be undone. Rough out basic forms before refining details. Study the stone’s grain and flaws before beginning. Use safety equipment—goggles, dust masks, and ear protection—as stone dust is hazardous. Traditional carving uses mallets and chisels; power tools accelerate the process but require careful control.

Wood Carving Understanding wood grain is fundamental. Carve with the grain when possible to prevent splitting. Different woods offer different properties: basswood and pine carve easily, hardwoods like oak and walnut offer durability and beautiful grain but require more effort, and exotic woods like ebony provide density and rich colors.

Gouges (curved cutting edges) excavate concave areas, while chisels create flat planes and details. V-tools cut sharp lines and decorative elements. Knives offer precision for small work. Begin with roughing out using large tools, gradually refining with smaller ones. Relief carving removes background while leaving designs projecting forward. In-the-round carving creates fully three-dimensional forms viewable from all angles.

Finish carved wood by sanding progressively through finer grits, then apply oils, waxes, or stains to protect and enhance grain patterns.

Foam Carving Polyurethane and polystyrene foams carve easily with hot wires, saws, and rasps. Ideal for architectural models, props, and temporary sculptures. Coat with plaster, resins, or specialized coatings for durability and finish. Foam’s lightness allows large-scale work without weight concerns.

Casting (Reproduction Process)

Mold Making Molds capture original sculptures for reproduction. Press molds work for relief sculptures—press clay into the mold to create positives. Waste molds (typically plaster) destroy during removal, used for single casts. Piece molds divide into sections for removing without destroying the mold. Flexible molds (silicone rubber) capture complex undercuts and produce multiple casts.

Create simple one-piece molds for basic forms. Complex sculptures require multi-part molds with registration keys ensuring proper alignment. Apply release agents (petroleum jelly, commercial releases) to prevent sticking. Build containment walls (cottle boards) around originals when pouring mold material.

Plaster Casting Pour plaster into molds to create solid or hollow casts. For hollow casts, slush liquid plaster around mold interiors, building up layers. Plaster expands slightly when setting, capturing fine detail. Remove casts after complete hardening (allow 24-48 hours for strength). Clean seams and surface imperfections with files and sandpaper.

Resin Casting Polyester and epoxy resins create durable, detailed casts. Mix resin with catalyst following manufacturer’s ratios precisely. Add pigments, metallic powders, or inclusions for varied effects. Pour into silicone or rubber molds. Resins require adequate ventilation and safety precautions. Cure times vary from hours to days depending on formulation and mass.

Metal Casting – Lost Wax Process This ancient technique produces bronze and other metal sculptures. Model originals in wax, encase in investment material (refractory plaster), then fire the mold, melting out the wax. Molten metal pours into the cavity, assuming the wax’s exact form. Break away investment after cooling, revealing the metal cast. Chase (refine) surfaces and apply patinas for color.

Foundries handle large-scale bronze casting, but small kilns and centrifugal casting enable studio practice. Lost-wax casting captures extraordinary detail, from fingerprints to delicate textures.

Sand Casting Pack sand mixed with binder around patterns, remove patterns leaving cavities, then pour molten metal. Simpler than lost-wax but less detailed. Suitable for aluminum and bronze. Green sand (clay-bonded) remains reusable, while resin-bonded sand provides better detail.

Construction and Assemblage

Welded Metal Sculpture Join metal pieces through fusion welding. MIG (Metal Inert Gas) welding suits beginners, feeding wire electrode through the gun. TIG (Tungsten Inert Gas) offers precision for thin materials and fine work. Arc welding uses stick electrodes for heavy steel. Learn proper technique, safety equipment (welding helmets, gloves, protective clothing), and fire prevention.

Build armatures from steel rods, expand with sheet metal, wire mesh, or found objects. Cut metal with plasma cutters, angle grinders, or acetylene torches. Grind, polish, or leave raw for different aesthetic effects. Apply patinas chemically or through heat for surface coloration. Seal with clear coats or waxes for protection.

Found Object Assemblage Transform existing objects into sculptures. Duchamp’s readymades pioneered this approach. Combine disparate elements through welding, bolting, riveting, or adhesives. Context and juxtaposition create meaning beyond individual components. Assemblage ranges from Picasso’s bull’s head (bicycle seat and handlebars) to Nevelson’s monumental wooden constructions.

Wire Sculpture Bend, twist, and join wire to create linear sculptures describing forms through contour and gesture. Aluminum wire bends easily, steel wire provides strength, and copper wire offers workability and warm color. Use pliers, jigs, and manual bending. Wire can be armatures for other materials or finished sculptures themselves. Calder’s mobiles demonstrate wire’s elegant possibilities.

Contemporary Techniques

Installation Art Create environmental experiences through spatial arrangements of objects, materials, light, and sound. Installations transform spaces, inviting viewer participation and interaction. Consider sight lines, movement patterns, and temporal experiences. Materials range from traditional (wood, metal) to unconventional (light, video, organic matter).

Kinetic Sculpture Incorporate movement through motors, wind, water, or viewer interaction. Balance, counterweights, and mechanical systems create motion. Calder’s mobiles move with air currents; Tinguely’s machines embrace chaotic mechanical motion. Consider rhythm, speed, and sound as sculptural elements.

Digital Fabrication 3D printing builds forms layer by layer from digital models. FDM printers melt plastic filament, SLA printers cure liquid resin with lasers, and SLS printers fuse powder. Create complex geometries impossible through traditional means. Scale limitations exist, but technology constantly advances.

CNC routers carve wood, foam, and soft materials from computer-controlled patterns. Laser cutters precisely slice sheet materials. These technologies enable precise repetition, complex geometries, and scaled production while maintaining handcrafted finishing touches.

Craft Techniques

Ceramics

Wheel Throwing Center clay on the spinning wheel, the fundamental challenge. Apply steady pressure while the wheel rotates, bringing clay to perfect center. Open centered clay by pressing downward and outward, creating the floor. Pull walls upward through repeated compressions, thinning and raising simultaneously. Shape rims, create curves, and refine profiles using hands, ribs, and sponges.

Leather-hard clay (partially dried, firm but still carvable) accepts trimming. Invert thrown forms on the wheel and shave away excess clay, refining footrings and wall thicknesses. Attach handles, spouts, and decorative elements at leather-hard stage using score-and-slip techniques.

Hand Building Pinch pots begin with clay balls shaped by thumb pressure and finger support. Ancient and meditative, this technique creates organic forms. Coil building stacks rope-like clay strands, blending and smoothing as you build. Control wall angles and create large vessels through coil construction.

Slab building uses rolled flat clay sheets. Cut shapes with templates, join with score-and-slip, and create architectural forms. Drape slabs over or into molds for consistent shapes. Combine techniques freely—many potters incorporate throwing, coiling, and slab work in single pieces.

Surface Decoration Incise patterns with tools while leather-hard. Carve away clay (sgraffito) revealing contrasting colors beneath slips. Apply paper-thin clay cutouts (sprig molds) for relief decoration. Stamp textures using found objects or custom tools.

Slips (liquid clay) provide colored surfaces. Brush, dip, or trail slips onto greenware or leather-hard clay. Underglazes offer broader color palettes, applied before glaze firing. Mishima involves inlaying contrasting slip into carved lines.

Glazing and Firing Glazes are glass-like coatings that melt during firing, creating color, texture, and waterproof surfaces. Apply by dipping, pouring, brushing, or spraying. Glaze chemistry affects final appearance—iron creates browns and greens, copper produces blues and reds, cobalt yields rich blues.

Bisque firing (first firing) hardens greenware to durable but porous bisqueware. Glaze firing (second firing) melts glazes to glassy finishes. Raku firing, a dramatic low-fire technique, involves removing red-hot pots and placing them in combustible materials, creating dramatic surface effects and metallic lusters through reduction.

Textile Arts

Weaving Interlace warp (lengthwise) and weft (crosswise) threads to create fabric. Looms hold warp under tension while weft passes over and under in patterns. Simple frame looms suit beginners; floor looms enable complex patterns and efficient production.

Plain weave alternates over-under. Twill weave creates diagonal patterns. Satin weave produces smooth, lustrous surfaces. Vary thread weights, colors, and materials for diverse effects. Tapestry weaving builds pictorial images through discontinuous weft.

Embroidery Stitch decorative patterns onto fabric. Basic stitches include running stitch, backstitch, satin stitch (filling areas with parallel stitches), chain stitch, and French knots. Combine stitches for complex imagery and textures. Embroidery enhances garments, creates pictorial art, and adds dimension to textiles.

Crewel embroidery uses wool on linen. Stumpwork creates raised, three-dimensional elements. Contemporary embroidery incorporates unconventional materials—wire, plastic, found objects—expanding traditional boundaries.

Felting Wool fibers interlock through heat, moisture, and agitation, creating dense felt fabric. Wet felting involves layering wool roving, applying hot soapy water, and agitating until fibers mesh. Needle felting uses barbed needles to entangle fibers, creating sculptural forms.

Felt accepts shaping, cutting, and stitching without fraying. Create vessels, garments, and sculptural work. Nuno felting combines wool with silk or other fabrics for hybrid textiles.

Jewelry and Metalsmithing

Fabrication Cut, shape, and join metal sheet and wire into jewelry and objects. Jeweler’s saw cuts intricate shapes with fine blades. Files refine edges and surfaces. Anneal (heat) metal to soften work-hardened material. Solder joins pieces using metal alloys that melt at lower temperatures than base metals.

Form bezels (frames) to hold stones. Create settings through prong, channel, or tension mounting. Forge metal through hammering on anvils and stakes, creating texture and dimensional forms. Raise vessels from flat sheet through controlled hammering over stakes.

Casting Cuttlefish bone casting uses the soft bone’s flat surface for simple mold making. Centrifugal and vacuum casting enable complex jewelry casting. Lose-wax technique (described earlier) suits intricate jewelry designs. Cast elements combine with fabricated components in mixed-technique pieces.

Surface Treatments Create patinas on copper, bronze, and silver through chemical reactions. Liver of sulfur darkens silver, creating antiqued effects. Heat patinas (flame coloring) produce rainbow oxidation on steel and titanium. Etch patterns using acid resists and ferric chloride. Texture through hammering, stamping, or reticulation (controlled melting).

Polish with progressive abrasives from coarse to fine, finishing with compounds for mirror surfaces. Alternatively, embrace matte, brushed, or oxidized finishes for contrast and character.

Glasswork

Lampworking Melt glass rods in torch flames, shaping beads, small sculptures, and scientific glassware. Borosilicate glass withstands thermal shock; soft glass offers vibrant colors. Build forms on mandrels (rods), layer colors, and create surface decorations. Slowly cool (anneal) finished work in kilns to prevent stress cracking.

Kiln-Forming Fusing melts glass pieces together in kilns. Layer colored glass, heat until edges round and surfaces merge. Slumping drapes heated glass over or into molds, creating dishes and sculptural forms. Casting involves melting glass into molds, similar to metal casting.

Glassblowing Gather molten glass from furnaces on blowpipes. Inflate by blowing air while continuously rotating. Shape with wooden blocks, metal tools, and paddles. Reheat repeatedly (glory holes) to maintain workability. Attach pontils for final shaping after removing blowpipes. This demanding technique requires team coordination and years of practice but produces vessels, sculptures, and architectural elements of breathtaking beauty.

Wood Crafts

Joinery Connect wood pieces without nails or screws through shaped joints. Mortise-and-tenon (hole and projection) creates strong, traditional joints. Dovetails interlock through trapezoidal tails and pins, prized for strength and beauty. Box joints stack interlocking fingers. Biscuit joints use football-shaped wafers in matching slots. Dowels create simple, effective connections.

Proper joinery ensures furniture stability and longevity. Glue joints with appropriate adhesives (PVA for interior, epoxy for strength, hide glue for traditional work). Clamp during drying for tight fits.

Turning Rotate wood on lathes while cutting with gouges and chisels. Spindle turning creates chair legs, balusters, and pens. Faceplate turning produces bowls and platters. Green wood turning works freshly cut, wet wood; dry turning uses seasoned lumber. Each offers different possibilities.

Master proper tool presentation, working from large cuts to fine details. Sand while spinning for smooth finishes. Apply finishes on the lathe for efficiency.

Marquetry and Inlay Cut thin wood veneers into patterns, fitting pieces together like puzzles. Glue assembled marquetry onto substrates. Marquetry creates pictorial images; parquetry forms geometric patterns. Inlay sets decorative materials (wood, metal, shell) into routed or carved recesses. These techniques have adorned furniture for centuries, adding visual richness through contrasting materials.

Safety and Studio Practice

All sculptural and craft work demands attention to safety. Wear appropriate protective equipment: respirators for dust and fumes, goggles for grinding and carving, gloves when handling sharp materials or chemicals, and hearing protection for loud processes. Ensure adequate ventilation when working with resins, patinas, or welding. Maintain organized, clean workspaces to prevent accidents.

Understand material properties and appropriate tools. Invest in quality equipment suited to your work. Practice fundamental techniques before attempting ambitious projects. Join workshops, guilds, or classes to learn from experienced practitioners. Document your processes through photography and notes, building knowledge for future work.

Conclusion

Sculpture and craft techniques offer infinite possibilities for creative expression. These methods range from ancient practices unchanged for millennia to cutting-edge technologies redefining making. Whether modeling clay, casting bronze, weaving textiles, or exploring digital fabrication, physical making connects us to material reality in increasingly digital times.

Master fundamentals, but don’t let technique overshadow expression. The best work emerges when skilled hands serve creative vision. Experiment fearlessly, embrace mistakes as learning opportunities, and develop your unique voice through persistent making. Three-dimensional creation offers tactile, spatial experiences unavailable in other media—engage with materials directly, and let them teach you their possibilities.